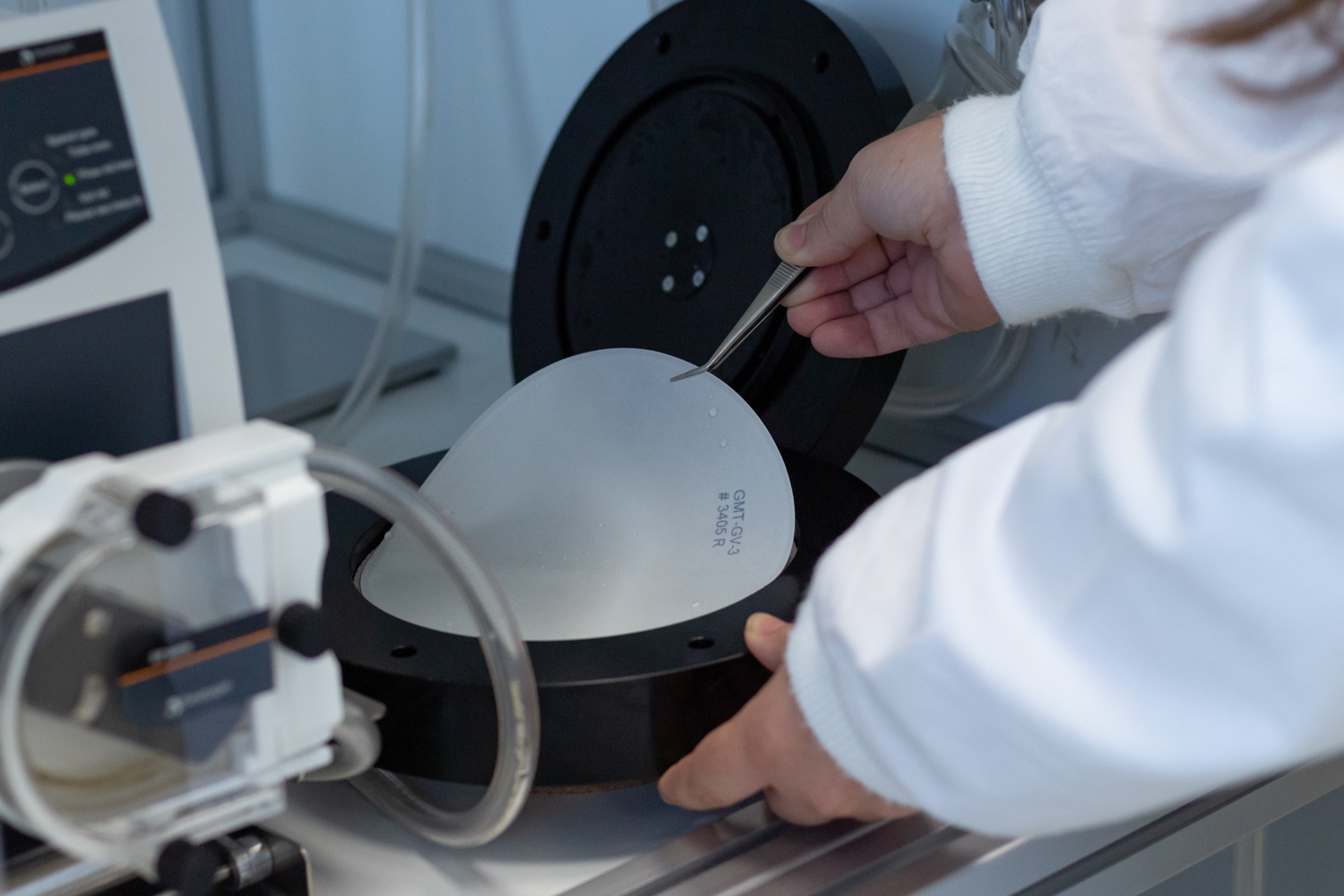

Membrane technology

Fraunhofer AWAM is dedicated to enhancing membrane technology through scientific and applied research aimed at improving the efficiency of separation processes. This involves studying the transport mechanisms and their effects on the performance of membranes. Using these insights, we either select or customize membrane systems for specific applications, particularly in water and wastewater treatment, gas purification, and the production of renewable low-carbon fuels.

Research and development concerning organic and inorganic membranes includes:

- Evaluation of membrane recovery, permeance, selectivity, and rejection through screening tests

- Long-term stability tests under relevant operating conditions to assess the influence of contaminants, fouling behaviour, and concentration polarization on the membrane performance

- Optimization of operational parameters, including pressure, temperature, and matrix composition, to enhance process performance.

Download material:

Fraunhofer Center for Advanced Water, Energy and Resource Management – AWAM

Fraunhofer Center for Advanced Water, Energy and Resource Management – AWAM