Liquid filtration

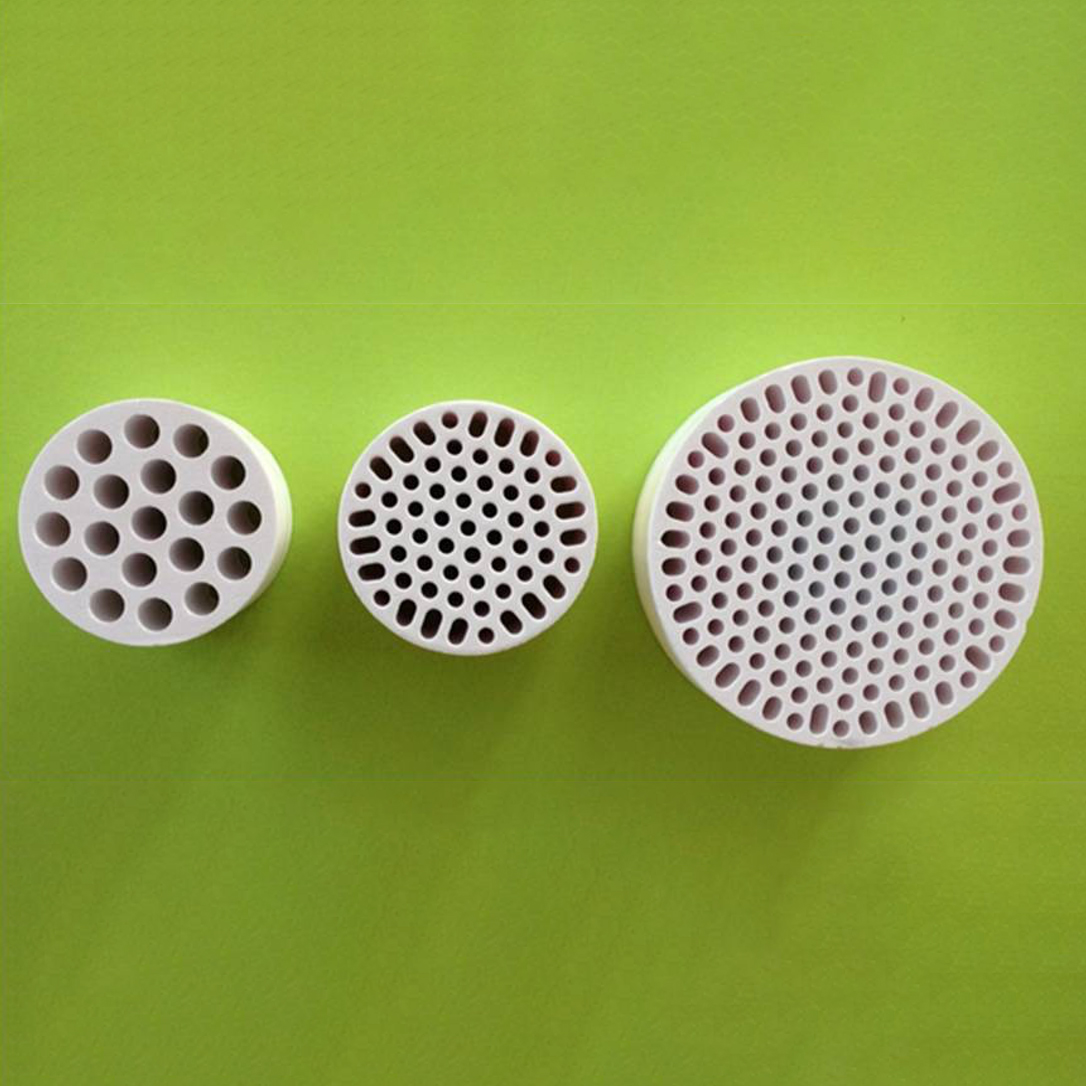

Fraunhofer Portugal AWAM can test ceramic porous membranes in lab- and pilot scale at realistic conditions. Furthermore, recommendations for the design and method of operation of technical plants have to be developed. Also pilot plants for customer specific on-site testing can be developed and built up.

> Development, construction and production of membrane (test) equipment, membrane housings and test plants (lab to pilot scale);

> Development of customer-specific membrane processes (laboratory tests, concept development and piloting);

> (Basic) process engineering and plant design (as support for customer implementation).

Fraunhofer Center for Advanced Water, Energy and Resource Management – AWAM

Fraunhofer Center for Advanced Water, Energy and Resource Management – AWAM